- Home

- Your water

- Reduced Pressure Zone valves

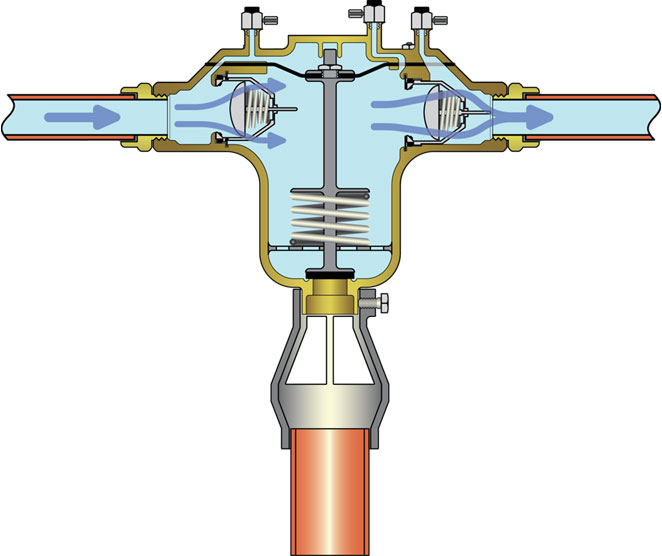

Reduced Pressure Zone valves

Reduced Pressure Zone (RPZ) valves are installed to prevent the backflow of fluids that represent a significant health hazard (fluid category 4).

This includes any fluids which contain:

- chemical, carcinogenic substances or pesticides (including insecticides and herbicides)

- environmental organisms of potential health significance.

Notifying us

Before installing an RPZ valve in premises already connected to the mains water supply, you must notify us first. This applies to all new RPZ valves, even if there are others already installed.

You can do this by completing a notification form and emailing it to us at Regulation5.Notification@wessexwater.co.uk or sending it by post to Wessex Water, Regulation 5, Developer Services, Claverton Down, Claverton, Bath BA2 7WW.

If the installation is within a development, the RPZ valve detail must be included in your new supply application.

In either case, please include the following information:

- the name and contact details of the person who will be responsible for the RPZ valve

- the make and model of the RPZ valve

- a description of the location where the valve will be installed

- whether it will be fed by mains or storage

- a plan or schematic drawing, if available, of the plumbing system where the RPZ valve will be installed.

Granting consent

We have 10 working days from the receipt of a formal notification to grant consent for the installation of the RPZ valve.

A work reference number will be provided for inclusion on the commissioning test certificate.

Installation and inspection

Once approval has been granted for the installation of the valve, it must be installed by an approved, registered contractor and in accordance with the Water Undertaker's Approved Installation Method (AIM) document.

Our regulations officers may require a site visit to inspect the RPZ to confirm it has been installed in accordance with the AIM document.

Testing

RPZ valves must be tested at a minimum of every 12 months unless a more regular frequency is required by the water undertaker.

RPZ tests must be carried out by an industry-approved tester. You can search for a local RPZ tester.

All test certificates must be emailed directly to us at RPZ@wessexwater.co.uk within 10 working days of the test being carried out.

Overdue tests

If we do not receive a passed test certificate from an approved tester within 14 working days of the due date of the test, we will attempt to contact the premises owner or person responsible for the RPZ valve.

A letter advising the test is overdue and must be carried out at the earliest opportunity will also be sent to the property.

If we do not receive any response a regulations officer will be arranged to visit the premises and carry out an inspection to assess the risk. The visit will also involve agreeing on a mutual resolution to the problem where possible.

Our last available resort will be to switch off the water supply to the premises until a passed RPZ test certificate has been received.

Reporting test failures

All test failures must be reported to us within at least 24 hours. Please email us at RPZ@wessexwater.co.uk and include details of the failure and the planned actions and associated timescales to resolve the issue.

The RPZ valve and fitting(s) it supplies must remain isolated until the RPZ valve can be repaired or replaced. The supply to the valve must not be reinstated until a satisfactory test pass is achieved.

If the risk is considered to be significant due to the nature of the water use at the premises, a regulation officer will be arranged to visit and assess the risk. As a last resort, the water supply to the premises may be switched off until the issue with the RPZ valve can be resolved.

Fluid Category 4 installation examples

An RPZ valve may be required for the following (please note this is not an exhaustive list):

- primary circuits and central heating systems in premises other than a house

- fire sprinkler systems using anti-freeze solutions

- mini-irrigation systems without fertiliser or insecticide applications, such as pop-up sprinklers or permeable hoses

- food preparation

- dairies

- bottle washing apparatus

- commercial dishwashing machines

- refrigerating equipment

- dyeing equipment

- industrial disinfection equipment

- printing and photographic equipment

- car washing and degreasing plants

- commercial clothes washing plants

- brewery and distillation plant

- water treatment plant or softeners using other than salt

- pressurised fire-fighting systems.

When not to use RPZ valves

RPZ valves are not suitable backflow prevention devices for the following processes:

- rainwater harvesting systems

- private water supplies (eg, boreholes, springs and wells)

- hose union taps

- vehicle pressure washers

- marinas, harbours, quays or other locations by lakes, rivers, canals and the sea.